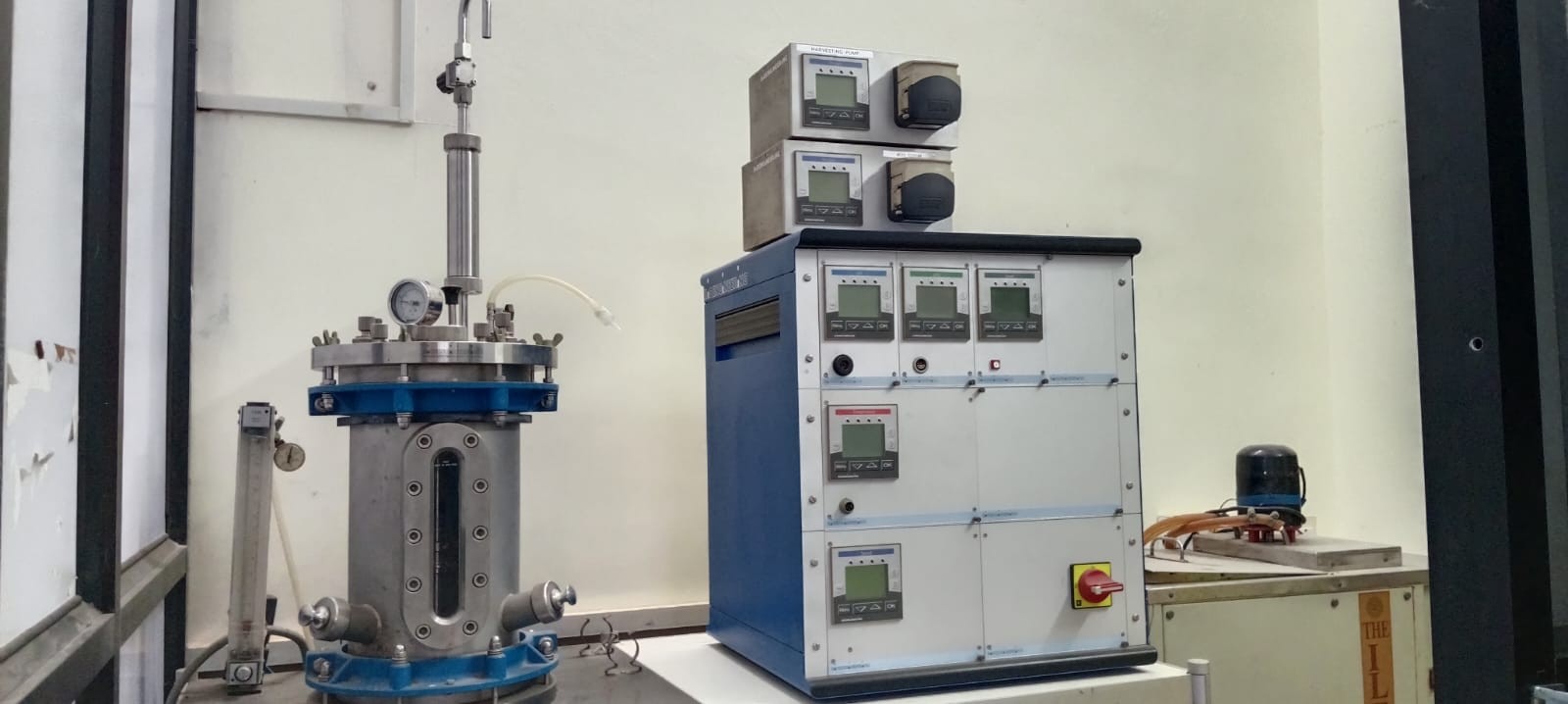

Make: Bio Engineering

Model: KLF20885

- Provides a controlled environment: It maintains optimal conditions for the growth of microorganisms.

- Allows for large-scale production: Fermenters are designed to grow microorganisms and produce metabolites in large quantities.

- Enables controlled chemical processes: It facilitates biochemical processes by providing nutrients and removing waste products.

- Food and Beverage:

- Production of fermented foods like yogurt, cheese, and soy products.

- Production of beverages such as beer and wine.

- Pharmaceuticals:

- Production of essential medications, including antibiotics, insulin, and vaccines.

- Production of therapeutic proteins, enzymes, and vitamin B12.

- Chemicals:

- Production of industrial chemicals like ethanol, butanol, and acetone.

- Production of organic acids, such as citric acid.

- Biotechnology:

- Used to grow and culture microorganisms or cells for various biotechnological applications.

- Creation of value-added products through the use of genetically engineered microorganisms.

- Waste Treatment:

- Used to decompose organic materials and convert them into more useful products.

Room No.: 225

SMV (Hexagon Building)

School of Bio Sciences and Technology

SMV (Hexagon Building)

School of Bio Sciences and Technology

Dr. Podili Koteswaraiah

School of Bio Sciences and Technology,

Vellore Institute of Technology - Vellore Campus,

Thiruvalam Road, Vellore, Tamil Nadu, India.

Landline: 0416-220 2556

Mobile: +91- 9840934792

Faculty in charge email id: koteswaraiahpodili@vit.ac.in

Instrument email id: sbst.fermenter@vit.ac.in

School of Bio Sciences and Technology,

Vellore Institute of Technology - Vellore Campus,

Thiruvalam Road, Vellore, Tamil Nadu, India.

Landline: 0416-220 2556

Mobile: +91- 9840934792

Faculty in charge email id: koteswaraiahpodili@vit.ac.in

Instrument email id: sbst.fermenter@vit.ac.in

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Per run | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |