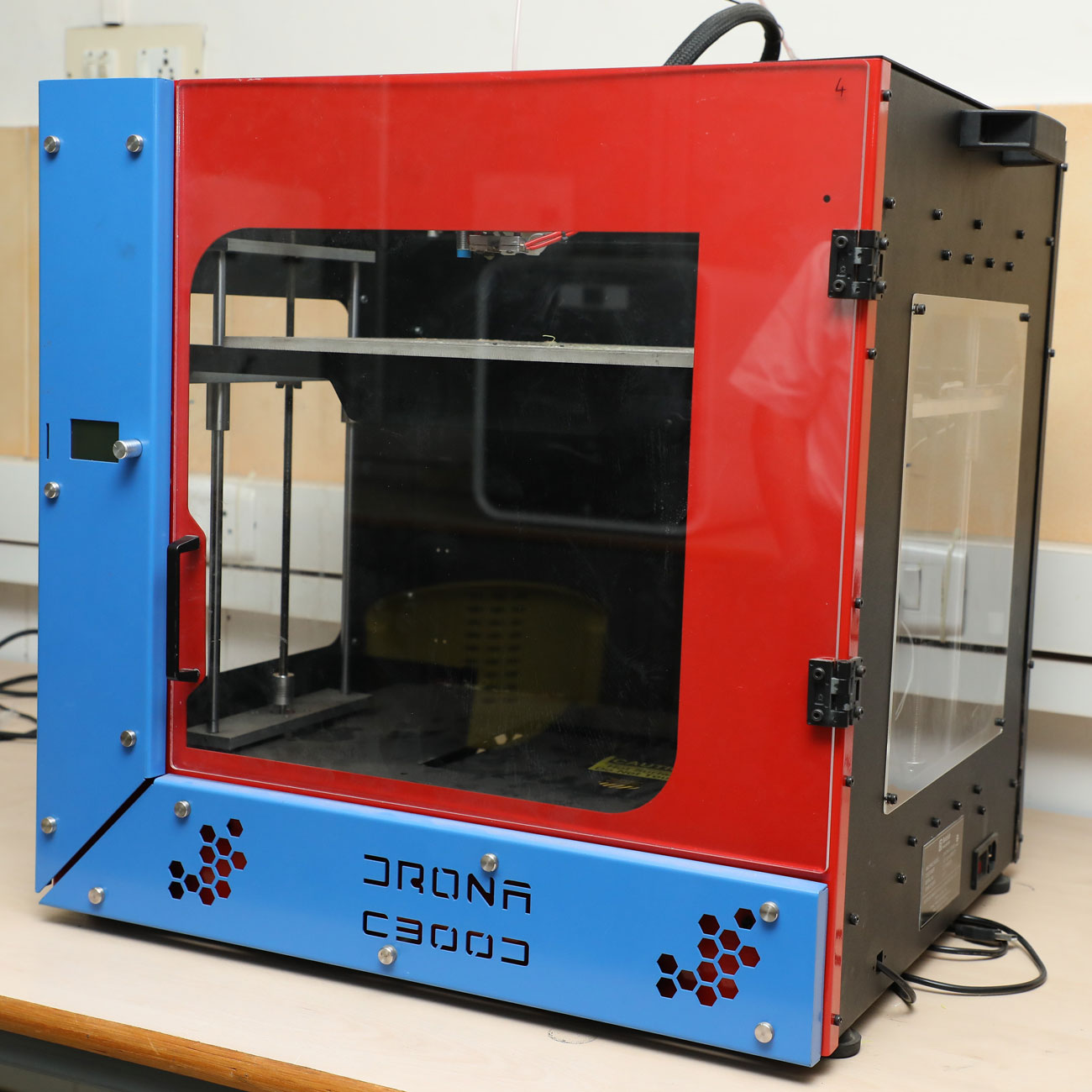

Make: Drona

Model: C300D

- Bed 300 mm3

- Filament dia 1.75 mm

- Layer capacity 0.1mm - 0.3mm

FDM 3D printing creates strong and durable parts out of most industrial grade thermoplastics. It is widely used for prototypes, final products and concept models.

Room No.: 202

Second floor

A.L. Mudaliyar Block

Digital Manufacturing Lab

School of Mechanical Engineering

Dr. Sugavaneswaran M,

Assistant Professor Sr. Grade 2,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.defp1@vit.ac.in

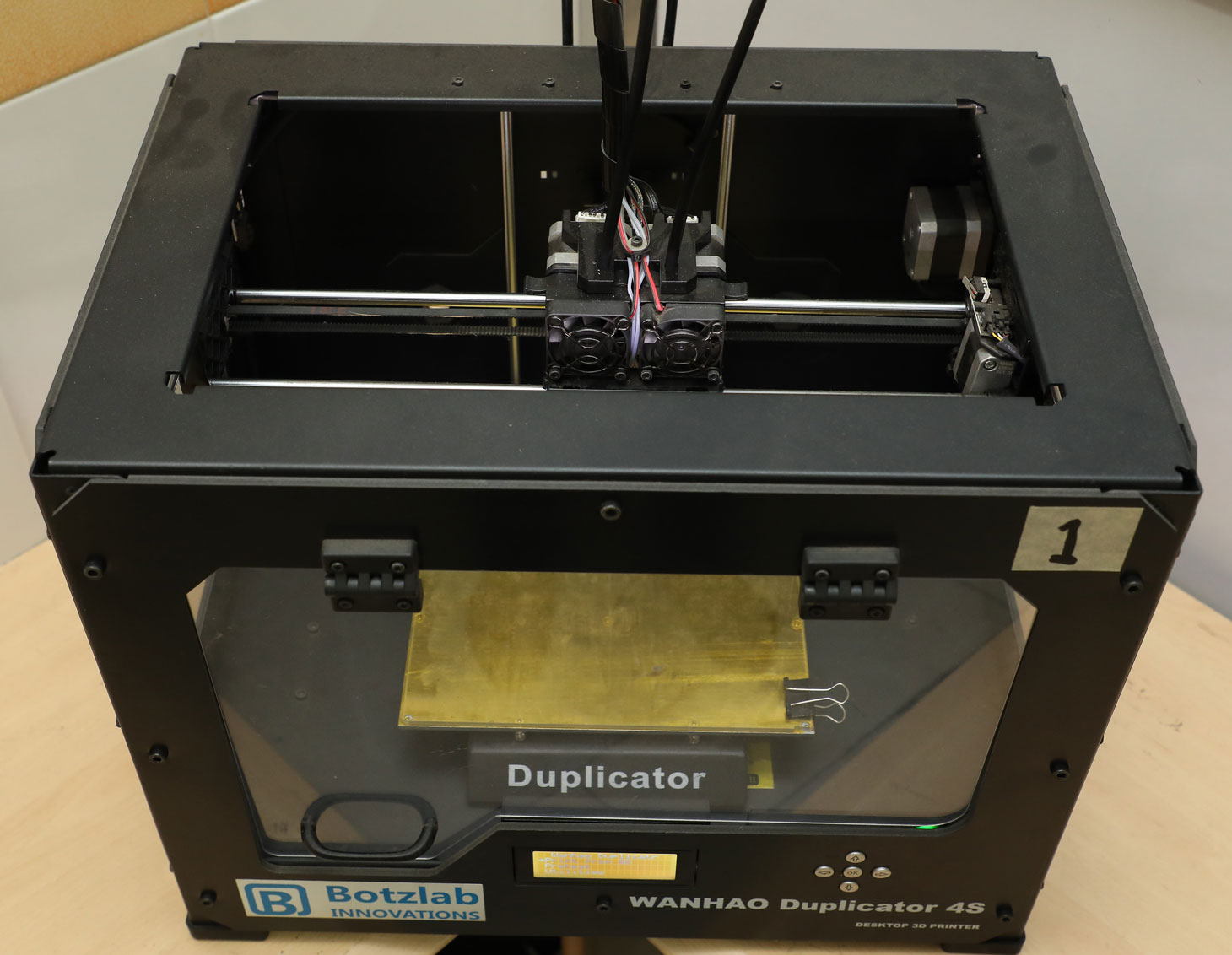

Make: Wanhao

Model: D4S

- Bed 200mm x140mm x 150mm

- Filament dia 1.75 mm

- Layer capacity 0.1mm - 0.3 mm

FDM printed parts are used for a massive amount of applications across industries.

Room No.: 202

Second floor

A.L. Mudaliyar Block

Digital Manufacturing Lab

School of Mechanical Engineering

Dr. Sugavaneswaran M,

Assistant Professor Sr. Grade 2,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.defp2@vit.ac.in

Make: Swamtec

Model: SwamEquip

- Frequency - 20 KHz

- Application : ultrasonic machining, stir casting, Ultrasonic grinding

For producing semisolid feedstock directly from molten metal, Ultrasonic vibration assisted machine is used for cutting ductile materials, hard-to machine alloys and hard-to machine steels

Room No.: G14,

Ground floor

GD Naidu block,

Advanced Material Processing and Testing Lab

School of Mechanical Engineering

Dr. R. Oyyaravelu,

Assistant Professor Sr. Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.ultrasonicvib@vit.ac.in

Phone: 0416 220 2221

Make: Kistler - Singapore

Model: 9257 B

- 6- Component force Dynamometer

- Measuring Range : -5 to 10 KN

- Operating Temperature : 0 to 70 oC

- Natural frequency : fn(x), fn(y) : 2.3 kHz, and fn(z) : 3.5 kHz.

- Sensitivity Fx, Fy : –7.5 pC/N, Fz : –3.7 pC/N.

Measure all of the components of the cutting force, are invaluable in research, tool manufacture and production technology. They are used in analysing, comparing and selecting materials, tools and machines.

Software

Kistler dynamometer software

Room No.: G14,

Ground floor

GD Naidu block,

Advanced Material Processing and Testing Lab

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

Dr. R. Oyyaravelu,

Assistant Professor Sr. Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Mobile: +91 98430 16937

Email: smec.mfmd@vit.ac.in

Email: royyaravelu@vit.ac.in

Office Phone: +91 – 416 – 220 2242

Mobile: +91 98430 16937

| S. No. | Experiment Details | Students (UG/PG)/Research Scholars from VIT | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

| 1 | FORCE MEASUREMENT DYNAMOMETER (MACHINING) | 1000/hr | 2000/hr | 2000/hr | 2000/hr | 2000/hr | 2000/hr | 2000/hr |

* Charges for per sample in INR (+ applicable GST)

Make: Electronica Hitech Machine Tools

Model: Job Master D-Zire

- Table Size, mm, 635 x 475 ;

- Work-tank Internal Dimensions are 800 x 650 mm;

- Main Table Travel X,Y mm,;

- Auxiliary Table travel U,V 400 x 300 mm,

- Wire diameter 0.25 mm

- Front Loading Machine

Wire EDM is most commonly used in mould and die manufacturing processes, particularly for extrusion dies and blanking punches. EDM can be used in everything from prototypes to full production runs, and is most often used to manufacture metal components and tools.

Software

- Macrowire2.5 version

Room No.: G14,

Ground floor

GD Naidu block,

Advanced Material Processing and Testing Lab

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

Dr. R. Oyyaravelu,

Assistant Professor Sr. Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Office Phone: +91 – 416 – 220 2242

Mobile: +91 98430 16937

E-Mail: smec.imte@vit.ac.in

Email: royyaravelu@vit.ac.in

| S. No. | Experiment Details | Students (UG/PG)/Research Scholars from VIT | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

| 1 | WIRE EDM | 200/hr | 350/hr | 350/hr | 350/hr | 350/hr | 350/hr | 350/hr |

* Charges for per sample in INR (+ applicable GST)

Make: Mahr

Model: Marsurf XR20

- Measuring ranges MFW 250 : 25 m, 250 m

- Profile types : D, P, W, R

- Cutoff wavelengths : 0.08 mm; 0.25 mm; 0.8 mm; 2.5 mm; 8 mm/free input

- Traversing lengths : Automatic; 0.56 mm; 1.75 mm; 5.6 mm; 17.5 mm, 56 mm

- Number of sampling lenghts : 1 to 50 (default: 5)

- Traversing speeds (Vt): 0.1 mm/s and 0.5 mm/s

To check the Surface quality of machined components

Room No.: G14,

Ground floor

GD Naidu block,

Advanced Material Processing and Testing Lab

School of Mechanical Engineering

Dr. R. Oyyaravelu,

Assistant Professor Sr. Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.surfprofilo@vit.ac.in

Phone: 0416 220 2221

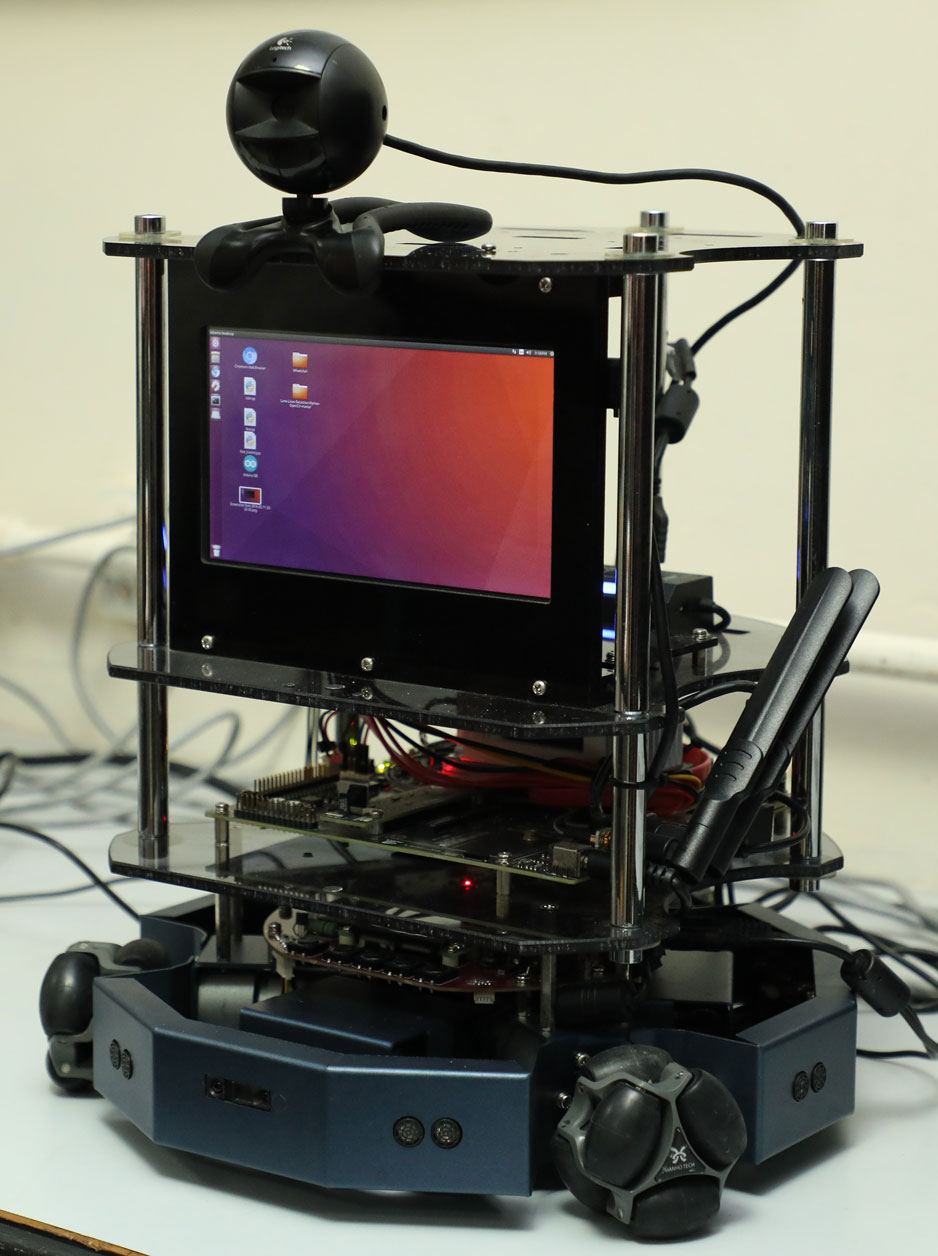

Make: Hanback, South Korea

Model: AI NVIDIA Roboex

- Real-time image processing service using the attached camera.

- Provides services for machine learning and deep learning using TensorFlow for high performance numerical computation

- Capable of high levels of computation speed with high-performance GPU.

- Object detection and obstacle recognition by intelligent robot application.

It can use in following applications: Puppy Recognition, Handwriting Recognition, Face Recognition, Lane Recognition and Object Recognition. AI robot based Smart farming, Ai robot based sustainable agriculture, AI robot vertical farming. Internet of robotic things. It can be used to learn Deep Learning with AI NVIDIA, RoboEX AI / Machine Learning / and Deep Learning using TensorFlow Image Processing.

Room No.: 172

First floor

GD Naidu Block

Mechatronics Lab

School of Mechanical Engineering

Dr. Ramakrishnan R,

Associate Professor Grade 1

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.ainvidia@vit.ac.in

Phone:0416 2202246

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| UG /PG Students from Academic Institution | 2000 |

| Research Scholar from Academic Institution | 2500 |

| Project Staff from Academic Institution | 3000 |

| Faculty Members from Academic Institution | 4000 |

| Research Scientist from R&D Organizations | 4500 |

| Industry Personnel from Industry | 5000 |

| Personnel from Non - Government Organization | 3000 |

Make: Basler

Model: Basler'ac A640

- Spindle error measurement and evaluation in machine tools

- Automated Surface defect detection and classification

- Dimensional measurement and inspection of components

- Object detection for Autonomous vehicles

- Sorting of defective and non defective items

- Counting of items using image processing techniques

- Stereo vision systems for depth measurement

- Camera calibration for automated inspection

Surface defect detection in weld joints, leather, manufactured components, spindle error measurement Customized high speed image processing, and inspection applications

Room No.: G02

Ground Floor

Souvenir Shop

Cyber Physical System Lab

School of Mechanical Engineering

Dr. Denis Ashok,

Professor Grade 2

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.hrcamnv@vit.ac.in

Make: Dongling

Model: ESS-005

Force sensor

- Model: 208C01

- Make: PCB piezotronics

- Sensitivity: 107.4 mV/N

Shaker

- Rated sine force: 5 kgf

- Max. Acceleration: 30 g

- Max. Displacement: 6 mm

- Frequency range: 5 to 10000 Hz

To identify the resonance by comparing response vibrations of the product to the vibrations on the shaker table.

Room No.: SOV 102

First floor

Souvenir Shop

Noise Vibration and Harshness Lab

School of Mechanical Engineering

Dr. Ramesh Babu V,

Assistant Professor Sr. Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.vts@vit.ac.in

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| UG /PG Students from Academic Institution | 1000 |

| Research Scholar from Academic Institution | 1000 |

| Project Staff from Academic Institution | 1000 |

| Faculty Members from Academic Institution | 1000 |

| Research Scientist from R&D Organizations | 1500 |

| Industry Personnel from Industry | 1500 |

| Personnel from Non - Government Organization | 1500 |

Make: Artis Technologies

Model: customized

- Velocity range: 15 to 1230 miles per second.

- Operating Temperature: 0'C to 50'C

- Pressure range: 0 to 16 bar.

- To measure the impact toughness of various materials (metals, ceramics etc.).

- To make fracture analysis of various materials (metals, ceramics etc.).

Room No.: G-25

Ground floor

GD Naidu Block

Dynamics and Vibrations Lab

School of Mechanical Engineering

Dr. Ramesh Babu V

Assistant Professor Sr. Grade 1

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: smec.lvbit@vit.ac.in

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| UG /PG Students from Academic Institution | 1000 |

| Research Scholar from Academic Institution | 1000 |

| Project Staff from Academic Institution | 1000 |

| Faculty Members from Academic Institution | 1000 |

| Research Scientist from R&D Organizations | 1500 |

| Industry Personnel from Industry | 1500 |

| Personnel from Non - Government Organization | 1500 |

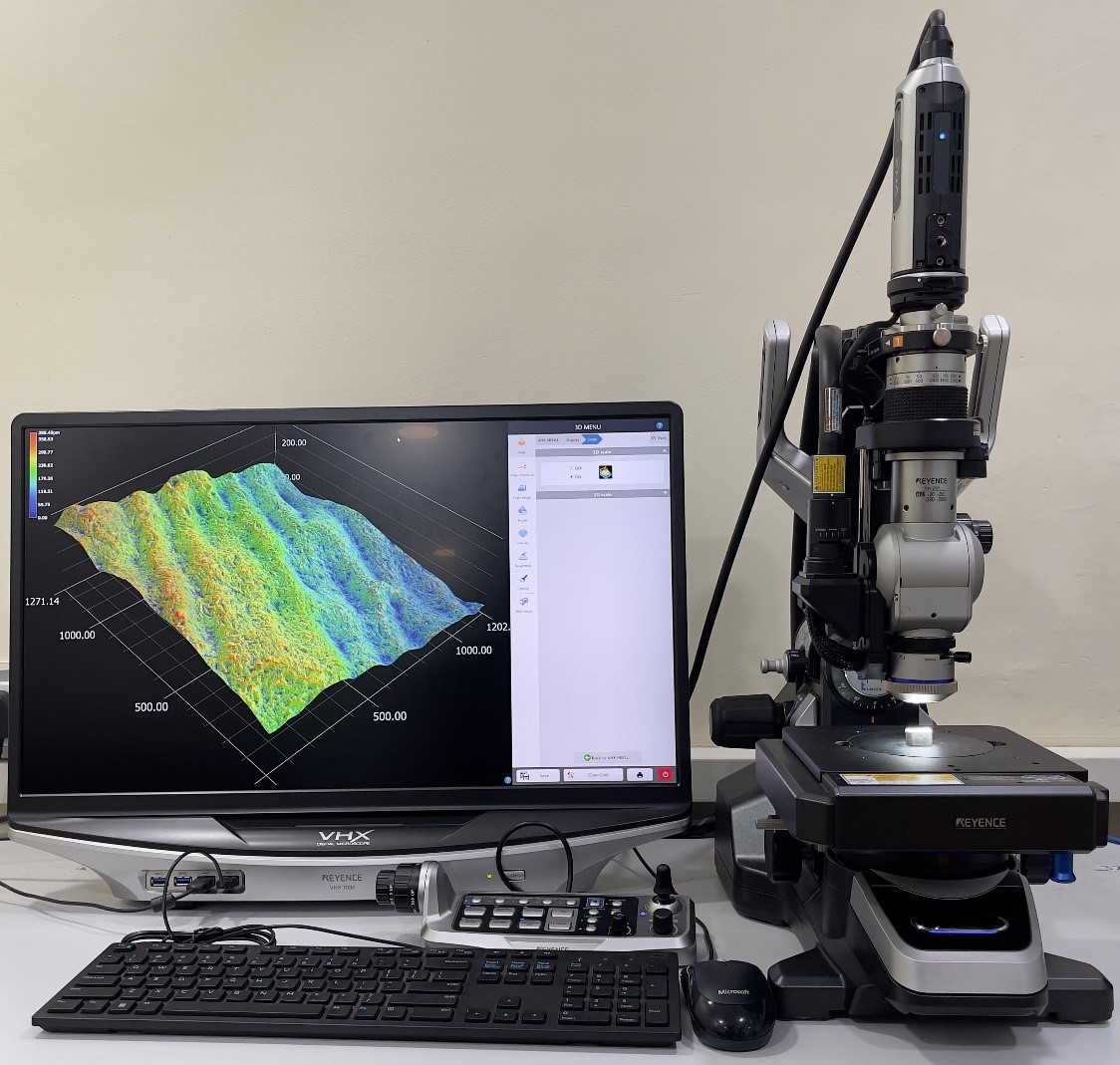

Make:

Model:

- 3D profile measurement

- Point to point height measurement

- 3D volume measurement

- Distance, angle , radius and area etc.

- Automatic edge detection

- Automatic area measurement

- Contamination analysis

First Floor

GD Naidu Block

Measurements Lab

School Of Mechanical Engineering

Associate Professor Grade 2

School of Mechanical Engineering

Vellore Institute of Technology, Vellore, INDIA-632014

Email: kdm.crf@vit.ac.in

External Users

| EQUIPMENT_NAME | UG /PG Students from Academic Institution (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institution (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) | Personnel from Non - Government Organization (in INR) |

| Keyence Digital Microscope-VHX-7000N-3D contour & surface roughness | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Keyence Digital Microscope-VHX-7000N- High Resolution Depth Composition and Image Stitching | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

Make: PerkinElmer

Model: NexION 1000

Analyser: Three-Quadrupole

Range: 7 to 238 amu (Li to U)

- ICP-MS is an analytical technique for the determination of the elemental composition of a sample.

- ICP-MS is superior to AAS and OES in terms of sensitivity and accuracy as it capable of detecting metals at concentrations as low as 0.25ppt.

Department of Manufacturing Engineering,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering.

Dr. Akella Siva Rama Krishna

Dr. Vasudevan R

G07, GDN Block,

Department of Manufacturing Engineering,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering,

E-mail: smec.icpms@vit.ac.in

| ANALYSIS | UG /PG Students from Academic Institution (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Personnel from Industry (in INR) | Personnel from Non - Government Organization (in INR) |

|---|---|---|---|---|---|---|---|

| Inductively coupled plasma-mass spectrometry - liquid sample | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

Make: EOS

Model: M290

| Build Volume: 200mmx200mmx250mm |

| Layer Thickness: 0.04mm-0.12mm |

| Laser Power: 400W |

| Laser Type: Ytterbium Fiber Laser |

| Laser Spot Size: 80 Microns |

| Scanning Speed: 7 m/s |

- 3D Profile Printing

- Metpol & Expose OT Monitoring

- Optimize parameter – laser power, layer thickness, hatch distance, laser speed

- Powders used - Stainless Steel, Titanium, Nickel Base Alloy, Aluminium

Department of Manufacturing Engineering,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering.

Dr. Raja K

Dr. Vasudevan R

G02, GDN Block,

Department of Manufacturing Engineering,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering,

E-mail: smec.metalam@vit.ac.in

| TESTING NAME | External -UG /PG Students/Research Scholars from Academic Institution (in INR) | External - Faculty Members/Project staff from Academic Institution (in INR) | External- Research Scientist from R&D Organizations (in INR) | External-Industry Personnel from Industry (in INR) |

|---|---|---|---|---|

| Inconel718 Alloy | 2500 | 2500 | 2500 | 2500 |

| Ti64 Grade23 | 4250 | 4250 | 4250 | 4250 |

Make: BRUKER

Model: SKYSCAN 1273

| X-Ray Source: 130KV |

| X-Ray Detector: 6MP |

| Object Size: 100mm X 200 mm |

| Object Weight: 15 Kgs |

- NDT Analysis.

- Internal defects like pores, cracks, etc.

- Find the pore sizes and porosity percentage.

- To find out two difference density materials.

Department of Manufacturing,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering.

Dr. Vasudevan R

G02, GDN Block,

Department of Manufacturing,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering

Email: smec.microct@vit.ac.in

| ANALYSIS NAME | UG /PG Students from Academic Institution (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institution (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) | Personnel from Non- Government Organizations (in INR) |

|---|---|---|---|---|---|---|---|

| MICRO CT SCANNER - FIRST 30 MINUTES | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| MICRO CT SCANNER - EVERY ADDITIONAL 30 MINUTES | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Make: BRUKER

Model: TS 77

| Indent Tip: Berkovich |

| Load: 9000 µN [max] |

| Speed: 2.0 µN |

- Indentation

- SPM Imaging

- Property Mapping

- DMA Analysis for Polymer Samples.

Department of Manufacturing,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering.

Dr. Vasudevan R

G02, GDN Block,

Department of Manufacturing,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering,

E-mail: smec.nanoindenter@vit.ac.in

| ANALYSIS NAME | UG /PG Students from Academic Institution (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institution (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) | Personnel from Non - Government Organization (in INR) |

|---|---|---|---|---|---|---|---|

| Nanoindenter (maximum six indentations) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Nanoindenter ? nano DMA | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

Make: ULVAC-PHI

Model: VersaProbe 4

- Elemental Scan (Survey + HR)

- Depth Profiling

- Line Profiling

- Mapping

- Ultraviolet Photoelectron Spectroscopy (UPS)

- Low-Energy Inverse Photoemission Spectroscopy (LEIPS)

Department of Manufacturing,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering.

Dr. Vasudevan R

G08, GD Naidu Block,

Department of Manufacturing,

Centre of Excellence in Additive Manufacturing,

School of Mechanical Engineering

E-mail: smec.xps@vit.ac.in

| ANALYSIS NAME | UG /PG Students from Academic Institution (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institution (in INR) | Research Scientist from R&D Organizations (in INR) | Personnel from Industry (in INR) | Personnel from Non - Government Organization (in INR) |

|---|---|---|---|---|---|---|---|

| XPS-Elemental Scan | 750 | 750 | 750 | 750 | 750 | 750 | 750 |

| XPS-Depth Profiling | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| XPS-Line Profiling | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| XPS-Mapping | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Ultra Violet Photoelectron Spectroscopy | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Low Energy Inverse Photoemission Spectroscopy | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 |

Make: New Field Engineers

Model: Two High Mill

- Roll Diameter – 105 mm

- Roll Width – 100 mm

- Roll Operating pressure Capacity up to 15 Ton

- Maximum Specimen Thickness – 6 mm

- Maximum Specimen Width – 50 mm

- Roll Peripheral Speed – 1 m/ min to 8 m/ min

Ground floor

GD Naidu block,

Metal forming Laboratory

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

Associate Professor,

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore - 632 014, Tamil Nadu, India

Email: jambeswar.sahu@vit.ac.in

Office Phone: +91 ‑ 416 ‑ 220 2236

Faculty in charge email id: jambeswar.sahu@vit.ac.in

Instrument email ID: smec.thrm@vit.ac.in

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Four High Rolling Mill per sample (Cold Rolling) | 500 | 500 | 500 | 500 | 1000 | 1000 |

| 2 | Two High Rolling Mill per sample (Hot Rolling) | 1000 | 1000 | 1000 | 1000 | 1500 | 1500 |

* Charges for per sample in INR (+ applicable GST)

Make: Legion Brothers

Model: Single cylinder VCR

- Engine combustion and performance study in CI mode with CRDI Open ECU.

- Engine Combustion and performance study in SI mode with Liquid Fuel PFI Open ECU.

- Engine combustion and performance study in CI mode with CRDI Open ECU , secondary fuel injection with Liquid fuel PFI Open ECU.

- Engine Combustion and performance study in SI Mode with Gaseous Fuel PFI Open ECU.

- Engine combustion and performance study in CI mode with CRDI Open ECU &secondary fuel injection with Gaseous fuel PFI Open ECU.

- Performance Studies ‑ Analyzing torque, power, brake specific fuel consumption, and efficiency under varying compression ratios.

- Combustion Analysis ‑ Investigating pressure‑crank angle, heat release, ignition delay, and combustion duration using data acquisition systems.

- Emission Studies ‑ Measuring CO, CO2, HC, NOx, and smoke emissions with different fuels and blends.

- Alternative Fuel Research ‑ Evaluating biodiesel, alcohols, and nanoparticle‑added fuels for feasibility in IC engines.

Engine testing lab, GDN Block

Vellore Institute of Technology (VIT), Vellore.

Associate Professor

Engine testing lab, GDN Block- G25A

Vellore Institute of Technology (VIT), Vellore - 632 014, Tamil Nadu, India

Faculty in charge - Email: pbaskar@vit.ac.in

Mobile : 9486114993

Instrument email ID: smec.vcre@vit.ac.in

| FEE DESCRIPTION | AMOUNT in Rs |

|---|---|

| Internal-UG/PG Students from Academic Institution- 1 test run | N. A |

| Internal-Research Scholar from Academic Institution- 1 test run | N. A |

| Internal -Faculty Members/ Project Staff- 1 test run | N. A |

| External-UG /PG Students from Academic Institution-1 test run | 1000 |

| External-Research Scholar from Academic Institution-1 test run | 2000 |

| External-Project Staff from Academic Institution- 1 test run | 2500 |

| External-Faculty Members from Academic Institution- 1 test run | 2500 |

| External-Research Scientist from R&D Organizations- 1 test run | 3000 |

| External-Industry Personnel from Industry- 1 test run | 4000 |

| External-Personnel from Non-Government Organization-1 test run | 4000 |

Make: Mahr surf

Model: GD120

- Measures Surface Roughness.

- Roughness Measurement for taper edge sample by tilting.

- Both Short and Long Length Probes Available for measuring cylinders’ inner and outer surface Roughness.

- Surface Roughness Measurement for Hollow Samples.

School of Mechanical Engineering (SMEC)

Vellore Institute of Technology (VIT), Vellore.

Professor

Department of Manufacturing Engineering

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore - 632 014, Tamil Nadu, India

Room No.: GDN138 Measurements lab, GD Naidu Block.

Vellore Institute of Technology - Vellore Campus,

Thiruvalam Road, Katpadi, Vellore – 632014, Tamil Nadu, India.

Phone: 0416 2202262

Email: smec.measurements@vit.ac.in

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Measuring sample thin film oil separation (re-usable column) - per sample | 500 | 500 | 500 | 500 | 1000 | 1000 |

| 2 | Metals samples like Grinding ,turning ,milling separation (re-usable column) - per sample | 500 | 500 | 500 | 500 | 1000 | 1000 |

* Charges for per sample in INR (+ applicable GST)

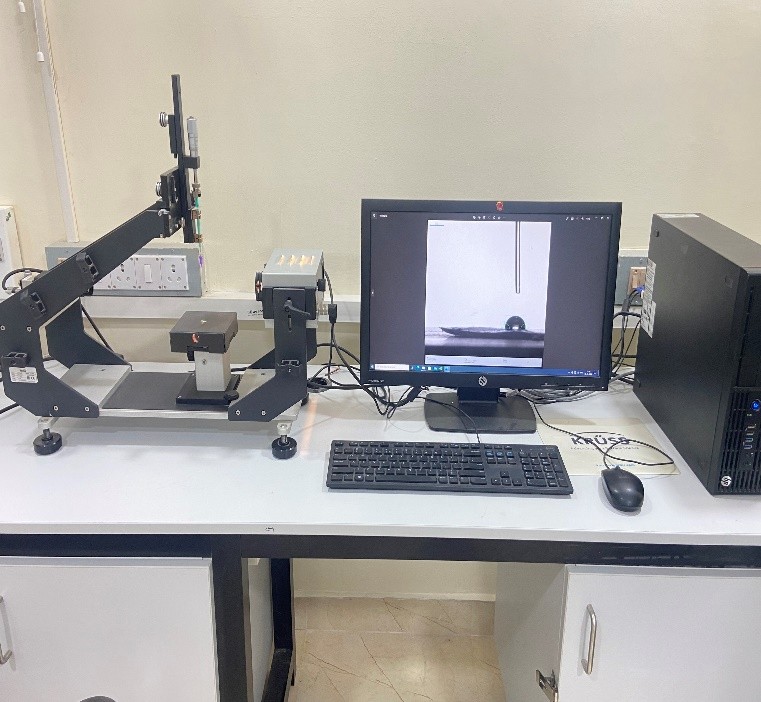

Make: Kruss

Model: DSA25B

- Water Contact Angle Measurement Device.

- Can be used on thin film, fibres, PLA Sample.

- Blood, Vegetable oil, coconut oil, can be used to measure Contact Angle.

School of Mechanical Engineering (SMEC)

Vellore Institute of Technology (VIT), Vellore.

Professor

Department of Manufacturing Engineering

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore - 632014, Tamil Nadu, India

Room No.: GDN138 Measurements lab, GD Naidu Block.

Vellore Institute of Technology - Vellore Campus,

Thiruvalam Road, Katpadi, Vellore – 632014, Tamil Nadu, India.

Phone: 0416 2202262

Email: smec.measurements@vit.ac.in

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Measuring sample Thinfilm,PLA Polymer ceramic coated oil separation (re-usable column) - per sample | 500 | 500 | 500 | 500 | 1000 | 1000 |

| 2 | Oil using Vegetable oil, coconut oil, acid separation (re-usable column) - per sample | 500 | 500 | 500 | 500 | 1000 | 1000 |

* Charges for per sample in INR (+ applicable GST)

Make: CH INSTRUMENTS

Model: CHI 650E

- Cyclic Voltammetry (CV)

- Linear Sweep Voltammetry (LSV)

- Differential Pulse Voltammetry (DPV)

- Square Wave Voltammetry (SWV)

- Electrochemical Impedance Spectroscopy (EIS)

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

SCHOOL OF MECHANICAL ENGINEERING

MATERIALS ENGINEERING TECHNOLOGY (MET) LAB,

139, GDN BLOCK,

VELLORE INSTITUTE OF TECHNOLOGY - VELLORE CAMPUS,

THIRUVALAM ROAD, VELLORE – 632 014, TAMIL NADU, INDIA.

Office Phone: +91 – 416 – 220 2258

Faculty in charge email id: smecmet@gmail.com; asandeep.s@vit.ac.in

Instrument email ID: Yet to receive

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Electrochemical Corrosion | 300 | 350 | 350 | 400 | 500 | 500 |

* Charges for per sample in INR (+ applicable GST)

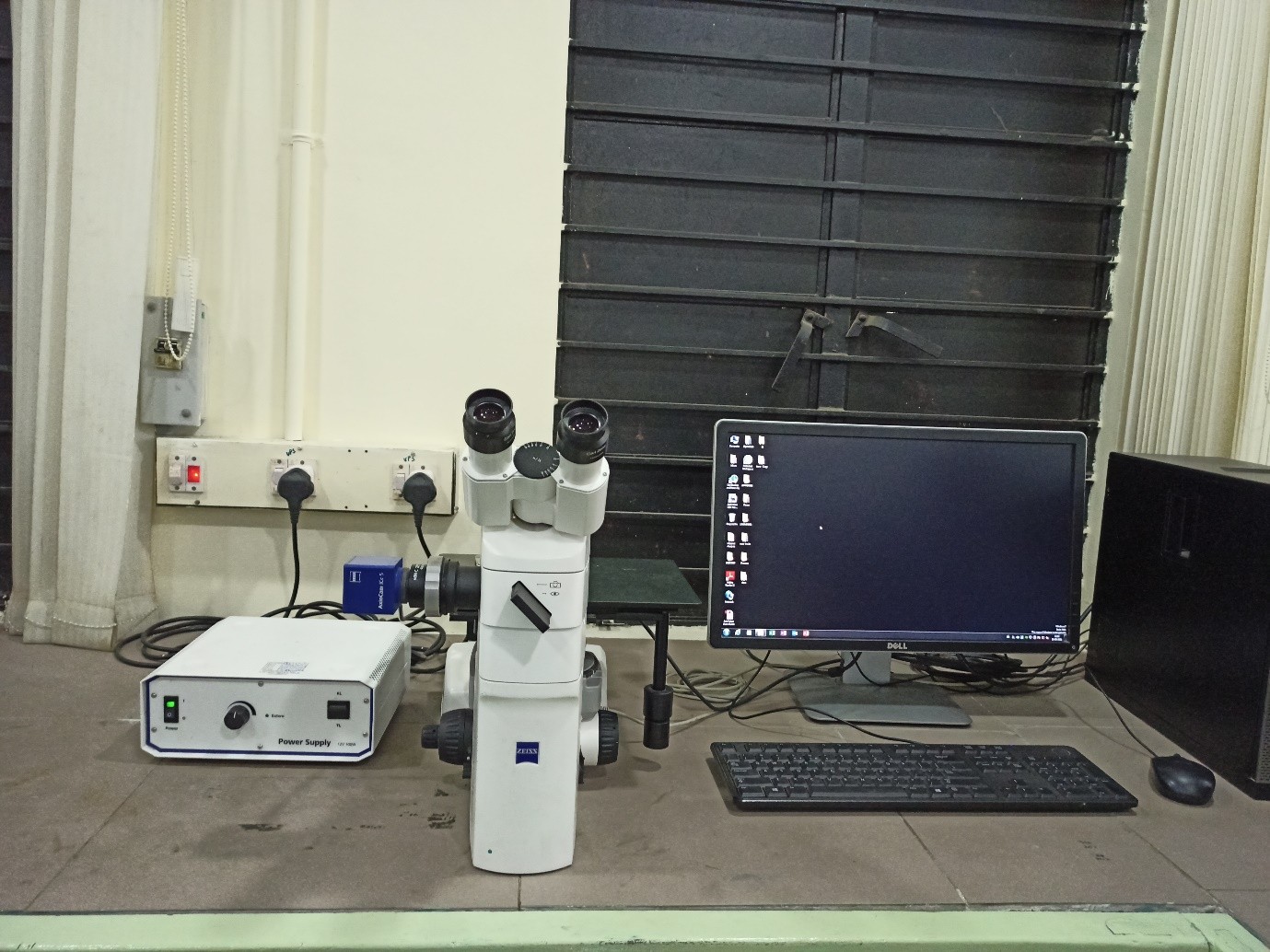

Make: CARL ZEISS

Model: AXIO VERT Al MAT

- The microscope supports a wide range of contrast methods for both reflected and transmitted light, allowing for detailed analysis of various sample types.

- The inverted design and wide range of objectives make it well-suited for large, heavy, and bulky samples.

- It can be used for tasks such as non-metallic inclusion analysis in steel, grain size analysis, and layer thickness measurement.

- The system includes smart technology to streamline workflows and improve reproducibility.

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

SCHOOL OF MECHANICAL ENGINEERING

MATERIALS ENGINEERING TECHNOLOGY (MET) LAB,

139, GDN BLOCK,

VELLORE INSTITUTE OF TECHNOLOGY - VELLORE CAMPUS,

THIRUVALAM ROAD, VELLORE – 632 014, TAMIL NADU, INDIA.

Office Phone: +91 – 416 – 220 2258

Faculty in charge email id: asandeep.s@vit.ac.in

Instrument email ID: Yet to receive

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Microscope | 350 | 350 | 400 | 500 | 500 | 250 |

* Charges for per sample in INR (+ applicable GST)

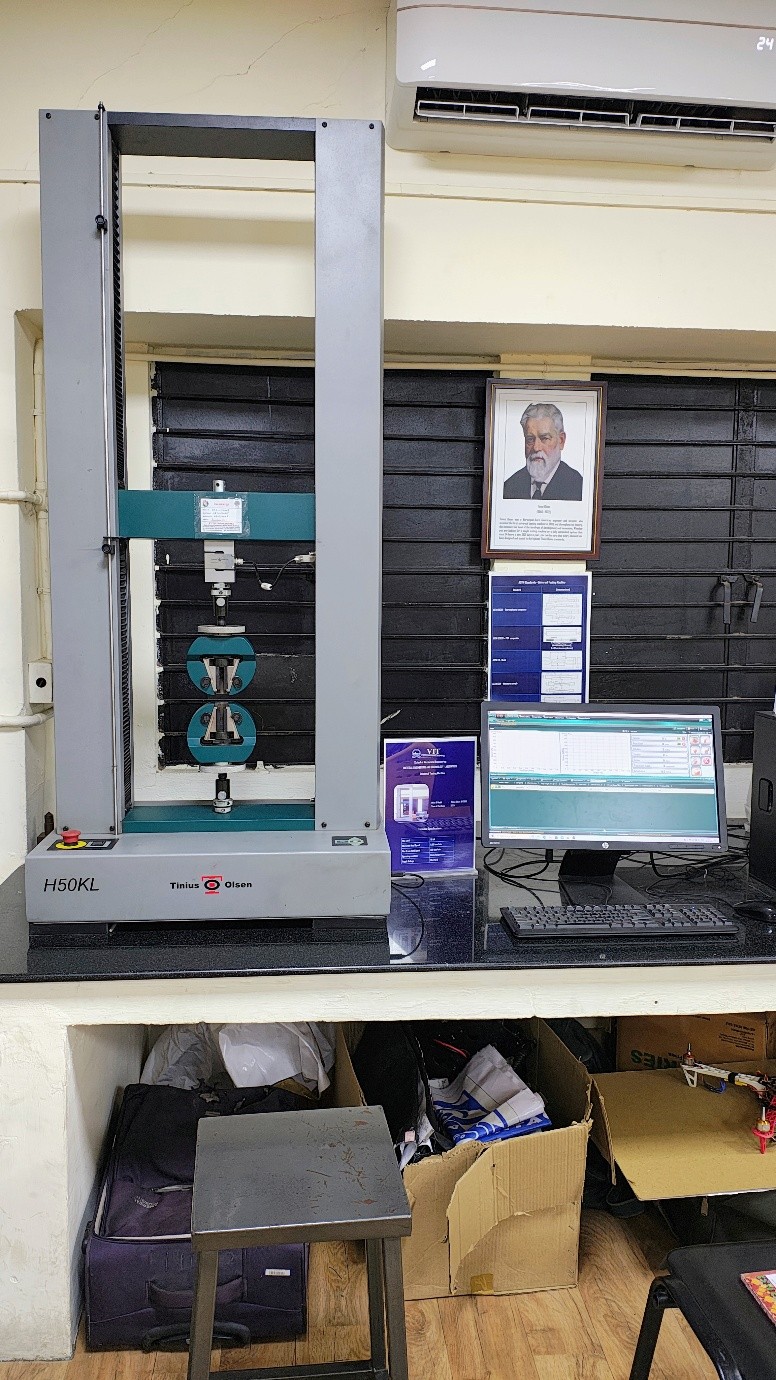

Make: TINIUS OLSEN

Model: HK50L

- With the right accessories, it is capable of performing Tensile and compression testing.

- Loadcells offer a high degree of accuracy (±0.5% of the applied load), ensuring reliable and repeatable results.

- Useful for testing of testing a diverse range of materials, including plastics, polymer composites, soft metals like Al.

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

SCHOOL OF MECHANICAL ENGINEERING

MATERIALS ENGINEERING TECHNOLOGY (MET) LAB,

139, GDN BLOCK,

VELLORE INSTITUTE OF TECHNOLOGY - VELLORE CAMPUS,

THIRUVALAM ROAD, VELLORE – 632 014, TAMIL NADU, INDIA.

Office Phone: +91 – 416 – 220 2258

Faculty in charge email id: asandeep.s@vit.ac.in

Instrument email ID: Yet to receive

| S. No. | Experiment Details | UG / PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Tensile Testing | 250 | 250 | 500 | 500 | 700 | 700 |

* Charges for per sample in INR (+ applicable GST)

Make: MITUTOYO

Model: HM-200

- The instrument is capable of both Vickers (HV) and Knoop (HK) hardness tests.

- Knoop is often preferred for very thin or brittle materials.

- The HM-200 series offers a wide range of selectable test forces, typically from 9.807 mN (1 gf) to 19.61 N (2000 gf). This allows it to test a variety of materials from very soft to very hard.

- It features an automatic turret that can switch between multiple objective lenses and the indenter. This greatly reduces manual intervention and potential operator error.

School of Mechanical Engineering

Vellore Institute of Technology (VIT), Vellore.

SCHOOL OF MECHANICAL ENGINEERING

MATERIALS ENGINEERING TECHNOLOGY (MET) LAB,

139, GDN BLOCK,

VELLORE INSTITUTE OF TECHNOLOGY - VELLORE CAMPUS,

THIRUVALAM ROAD, VELLORE – 632 014, TAMIL NADU, INDIA.

Office Phone: +91 – 416 – 220 2258

Faculty in charge email id: asandeep.s@vit.ac.in

Instrument email ID: Yet to receive

| S. No. | Experiment Details | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|

| 1 | Hardness Tester | 250 | 350 | 350 | 400 | 500 | 500 |

* Charges for per sample in INR (+ applicable GST)

Make: Delta power controls

Model: 240

Temperature (max): 1200℃.

Thermocouple type: R-Type

Floor: First floor,

Block: GD Naidu block,

Laboratory: Composites Laboratory,

School: School of Mechanical Engineering (SMEC),

Vellore Institute of Technology (VIT), Vellore.

Assistant Professor Sr.

School of Mechanical Engineering,

Vellore Institute of Technology (VIT), Vellore-632014, Tamil Nadu, India.

Office Phone: 0416-2202224.

Faculty in charge email id: deepa.a@vit.ac.in

| S. No. | Experiment Details | Students (UG/PG)/Research Scholars from VIT | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|---|

| 1 | High Temperature Silicon Carbide Tubular Vacuum Furnace (Per Melt) | 1000 | 2000 | 2000 | 2000 | 2000 | 2500 | 3000 |

* Charges for per sample in INR (+ applicable GST)

Make: SPECTRO AMETEK

Model: XHH03

- Instantly identify materials and their chemical composition from any location.

- Lightweight and portable.

- User-friendly Design.

- Material Verification.

- Manufacturing and Quality Control.

- Geology & Mining.

Floor: First floor,

Block: GD Naidu block,

Laboratory: Composites Laboratory,

School: School of Mechanical Engineering (SMEC),

Vellore Institute of Technology (VIT), Vellore.

Assistant Professor Sr.

School of Mechanical Engineering,

Vellore Institute of Technology (VIT), Vellore-632014, Tamil Nadu, India.

Office Phone: 0416-2202224.

Faculty in charge email id: deepa.a@vit.ac.in

| S. No. | Experiment Details | Students (UG/PG)/Research Scholars from VIT | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|---|

| 1 | Per Sample | 500 | 1500 | 1500 | 2000 | 2000 | 2500 | 3000 |

* Charges for per sample in INR (+ applicable GST)

Make: Tinius Olsen

Model: H10KL

Materials: Rigid plastics, Polymer Composites, Fibre Reinforced plastics, Thin films

Software: HORIZON

Floor: First floor,

Block: GD Naidu block,

Laboratory: Composites Laboratory,

School: School of Mechanical Engineering (SMEC),

Vellore Institute of Technology (VIT), Vellore.

Assistant Professor Sr.

School of Mechanical Engineering,

Vellore Institute of Technology (VIT), Vellore-632014, Tamil Nadu, India.

Office Phone: 0416-2202224.

Faculty in charge email id: deepa.a@vit.ac.in

| S. No. | Experiment Details | Students (UG/PG)/Research Scholars from VIT | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

|---|---|---|---|---|---|---|---|---|

| 1 | Tensile, Flexure, Compression, (500N, 10KLN) | 200 | 400 | 400 | 400 | 400 | 600 | 800 |

* Charges for per sample in INR (+ applicable GST)

Make: RV Machine

Model: RV machine & FSW 30

Specification

| Speed | 3000 rpm |

| Z axis load | 30kN |

| Z axis travel | 300 mm |

| X axis travel | 300 mm |

| Y axis travel | 100 mm, manual |

| Head tilt angle | ± 5 degree |

|

Controller: Force & Position Data Acquisition: Spindle rpm &Force |

Aerospace: Welding aircraft panels, fuel tanks, and structural components.

Electronics: Sealing battery enclosures and heat sinks.

Shipbuilding: Assembling decks, hulls, and bridges with corrosion-resistant joints.

Ground Floor

GD Naidu Block,

Welding Lab

School of Mechanical Engineering

Associate Professor Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: atul.kumar@vit.ac.in

Phone: +91 8394880897

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| Internal-UG /PG Students from Academic Institution | NA |

| Internal-Research Scholar from Academic Institution | NA |

| Internal-Faculty Members /Project Staff from Academic Institution | NA |

| External-UG /PG Students from Academic Institution | 1000/hr |

| External -Research Scholar from Academic Institution | 1000/hr |

| External -Faculty Members /Project Staff from Academic Institution | 1000/hr |

| External-Faculty Members from Academic Institution | 1000/hr |

| External-Research Scientist from R&D Organizations | 2000/hr |

| External-Industry Personnel from Industry | 2000/hr |

Make: WARPP Engineers Pvt. Ltd.

Model: HBS-50

Specification

| Parameter | Specification |

|---|---|

| Load Capacity | 50 kg |

| Table Diameter | ~ 300 mm |

| Table Height | ~ 400-500 mm |

| Tilt Angle | 0° - 90° (manual/motorized, model dependent) |

| Rotation Speed | 0.1 - 2 rpm (variable, electronic control) |

| Rotation Control | Forward / Reverse switch, variable speed knob |

| Drive Motor | AC/DC geared motor (low-speed, high-torque) |

| Power Supply | 220V / 415V, 50 Hz (model dependent) |

Circumferential welding: Around pipe circumference (rotating pipe/torch).

Straight fillet welds: Pipe supports and saddles.

Fabrication: Oil & gas, boiler tubes, structural pipe assemblies.

Ground Floor

GD Naidu Block,

Welding Lab

School of Mechanical Engineering

Associate Professor Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: atul.kumar@vit.ac.in

Phone: +91 8394880897

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| Internal-UG /PG Students from Academic Institution | NA |

| Internal-Research Scholar from Academic Institution | NA |

| Internal-Faculty Members /Project Staff from Academic Institution | NA |

| External-UG /PG Students from Academic Institution | 1000/hr |

| External -Research Scholar from Academic Institution | 1000/hr |

| External -Faculty Members /Project Staff from Academic Institution | 1000/hr |

| External-Faculty Members from Academic Institution | 1000/hr |

| External-Research Scientist from R&D Organizations | 2000/hr |

| External-Industry Personnel from Industry | 2000/hr |

Make: Kemppi

Model: Kemppi & X8

Specification

| Rated Current | 600A |

| Connection Voltage | 380-460V |

| Frequency | 50 Hz |

| Output 100% ED | 440A |

| Output 60% ED | 530A |

|

Cooling: Water cooled Continuous and Pulsed Mode MIG and MAG welding MMA welding |

Construction: Heavy-duty applications in construction, such as fabricating steel beams for bridges and buildings, rely on MIG welding for strong and durable joints.

Manufacturing and fabrication: Its high productivity and efficiency make MIG welding a primary choice for high-volume manufacturing of appliances, machinery, and other fabricated metal products.

Repairs and maintenance: MIG welding can be used to repair worn-out parts by adding new material, such as on railway tracks or other heavy equipment.

Ground Floor

GD Naidu Block,

Welding Lab

School of Mechanical Engineering

Associate Professor Grade 1,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: atul.kumar@vit.ac.in

Phone: +91 8394880897

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| Internal-UG /PG Students from Academic Institution | NA |

| Internal-Research Scholar from Academic Institution | NA |

| Internal-Faculty Members /Project Staff from Academic Institution | NA |

| External-UG /PG Students from Academic Institution | 1000/hr |

| External -Research Scholar from Academic Institution | 1000/hr |

| External -Faculty Members /Project Staff from Academic Institution | 1000/hr |

| External-Faculty Members from Academic Institution | 1000/hr |

| External-Research Scientist from R&D Organizations | 2000/hr |

| External-Industry Personnel from Industry | 2000/hr |

Make: Apex Innovations

Model: 240

Specification

|

Make Kirloskar, Single cylinder, 4 stroke, water cooled, stroke 110 mm, bore 87.5 mm, 661 cc. Power 3.5 KW @ 1500 rpm, CR range 12-18. | |

| ECU | Programmable open ECU with necessary wiring harness, MAP/MAPT, Pressure control valve, Rail pressure control/FDP, Fuel pump and main relay control, Peak And hold low impedance Injector, EGT, CLT, custom sensor, effective APP control | |

| EGR | Watercooled,SS304,Range0-15% | |

| Injector | Type Solenoid driven | |

| Piezo sensor | Combustion: Range 350 Bar with low noise cable | |

| Crank angle sensor | Resolution1Deg, Speed 5500RPM with TDC pulse. | |

| Data acquisition device | Analog inputs: 16 SE/8 DIFF; Digital I/O: 8; Analog outputs: up to 2; counters 2 x 32 bit; Sample rate: 250 kS/s; Resolution: 16- bit; Analog input Vmax ±10V of AI GND; High speed multifunction USB DAQ card | |

| Temperature sensor | TypeRTD,PT100andThermocouple,TypeK,Range0-1200DegC | |

| Temperature transmitter | Type 2 wire, Input RTD PT100, Range 0-100 Deg C, Output 4-20 mA and Type 2 wire, Input Thermocouple, Range 0-1200 Deg C | |

| Load Sensor indicator | Load cell, type strain gauge, range 0-50Kg Digital, Range0-50Kg, | |

| Fuel flow transmitter | DPtransmitter,Range0-500mm WC | |

| Airflow transmitter | Pressure transmitter, Range(-)250mmWC | |

| Rota meter | Engine cooling 40-400 LPH, Calorimeter 25-250 LPH |

The origination of the idea of variable compression ratio was the desire to use it for the engine supplying fuels with different properties; it is the so-called flex-fuel Capability.

The development of VCR technology says something about the potential for reducing fuel consumption.

The VCR technology enables a significant extension of the “downsizing” range, allowing further reduction of the displacement volume and the use of even higher boosting pressures. It is estimated that this method of adjusting the working parameters of the spark-ignition engine can result in a reduction in the fuel consumption by up to 30% without a significant increase of toxic exhaust compound emission.

VCR technology is the possibility of effective implementation of advanced, low-temperature LTC combustion processes (low-temperature combustion). They are characterized by extremely low emission levels of toxic compounds as a result of high complementarily of the combustion phase but conducted under conditions with reduced charge temperature.

Ground floor

GD Naidu block,

Thermal Engineering System Lab

School of Mechanical Engineering

Professor Grade 2,

School of Mechanical Engineering,

VIT, Vellore, TN-632014.

Email: vincent.wilson@vit.ac.in | Thermalengineeringg11@gmail.com

Phone: +91-416-220 2227

| User Type | Charges (INR) (+ applicable GST) |

|---|---|

| Internal-UG /PG Students from Academic Institution | NIL |

| Internal-Research Scholar from Academic Institution | NIL |

| Internal-Faculty Members /Project Staff from Academic Institution | NIL |

| External-UG /PG Students from Academic Institution | 2200 |

| External-Research Scholar from Academic Institution | 2200 |

| External-Project Staff from Academic Institution | 2200 |

| External-Faculty Members from Academic Institution | 2200 |

| External-Research Scientist from R&D Organizations | 2200 |

| External-Industry Personnel from Industry | 2200 |

| External-Personnel from Non - Government Organization | 2200 |

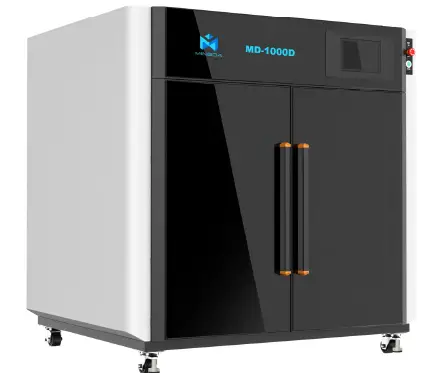

Make: MINGDA

Model: MINGDA MD600

SPECIFICATION

| Print Size | 600 x 600 x 600 |

| Layer Thickness | 0.3 mm |

| Extruder Temperature | 300 Degree |

| Bed Temperature | 100 Degree |

| Nozzle Diameter | 0.4 mm |

| Material | PLA,ABS,PLA-CF,ABS-CF,CF |

FDM 3D printing creates strong and durable parts out of most industrial grade thermoplastics. It is widely used for prototypes, final products and concept models.

The system benefits applications involving the study of:

- 3D Profile Printing

Room No.: G02

Ground Floor

GD Naidu Block,

Lab : Centre of Excellence in Additive Manufacturing

School of Mechanical Engineering

Dr.Raja.K

Professor,

School of Mechanical Engineering,

Vellore Institute of Technology,

Vellore, 632014

Email: kumar.raja@vit.ac.in

| User Type | Charges (INR) (+ applicable GST) | |

|---|---|---|

| ABS,PLA,ETC | PLA CF,ABSCF,PLA GF, | |

| Internal-UG /PG Students/Research Scholar from Academic Institution | 250 | 500 |

| Internal-Faculty Members /Project Staff from Academic Institution | 250 | 500 |

| External-UG /PG Students/Research Scholar from Academic Institution | 500 | 750 |

| External -Faculty Members /Project Staff from Academic Institution | 500 | 750 |

| External-Research Scientist from R&D Organizations | 500 | 750 |

| External-Industry Personnel from Industry | 1000 | 1500 |

* Charges for per sample in INR (+ applicable GST)

Make: Instron

Model: 8801

- Max.working pressure :207 bar

- Dynamic load capacity : Up to 100 kN (22,500 lbf) axial force capacity

- Operating environment: 10 to 38 °C

- Load Cell: Patented Dynacell load cell features compensation for inertial loads caused by heavy grips and fixtures.

- Actuator Stroke is 150 mm, No. of Columns 2, Actuator Position Base Frame Stiffness 390 kN / mm.

Instron measures tensile, compression, fatigue, testing a variety of materials and range of applications.

Instron UTM Software

- The Integrates with specialized software such as WaveMatrix™ for dynamic tests, Bluehill® Universal for quasi-static tests, and Bluehill Fracture for pre-cracking.

Versatile Systems:

- Used in systems ranging from basic servo hydraulic fatigue testers to complex cruciform biaxial test systems.

Room No.: G 14, GDN Block, Advanced Materials Processing and Testing Lab,

School of Mechanical Engineering.

Vellore Institute of Technology (VIT), Vellore.

Dr. R.Oyyaravelu

Assistant Professor

School of Mechanical Engineering.

Vellore Institute of Technology (VIT), Vellore - 632 014, Tamil Nadu, India

Office Phone: +91 – 416 – 220 2242

Mobile: +91 98430 16937

Email: royyaravelu@vit.ac.in

E-Mail: smec.imte@vit.ac.in

| S. No. | Experiment Details | Students (UG/PG)/Research Scholars from VIT | UG /PG Students from Academic Institutions (in INR) | Research Scholar from Academic Institution (in INR) | Project Staff from Academic Institution (in INR) | Faculty Members from Academic Institutions (in INR) | Research Scientist from R&D Organizations (in INR) | Industry Personnel from Industry (in INR) |

| 1 | Servo Universal Testing Machine - Instron | 1000/hr | 2000/hr | 2000/hr | 2000/hr | 2000/hr | 2000/hr | 2000/hr |